EEVs offer precision and adaptability for complex systems, while TXVs are known for their reliability and are a cost-effective choice for simpler HVAC setups.

Expansion valves are crucial components in HVAC systems that control refrigerant flow, ensuring efficient cooling.

we’ll compare two common types: Electronic Expansion Valves (EEV) and Thermostatic Expansion Valves (TXV).

What Are Expansion Valves?

Table of Contents

ToggleExpansion valves play a key role in regulating the flow and pressure of refrigerant in HVAC systems. They are vital for efficient cooling. We’ll focus on two types: EEV and TXV.

EEV vs. TXV: How They Work

Electronic Expansion Valves (EEV)

EEVs are modern and precise. They use electronic sensors to monitor temperature, pressure, and superheat. Based on this data, they adjust the refrigerant flow in real time. This makes them great for complex systems, such as commercial air conditioning, where quick and precise control is needed.

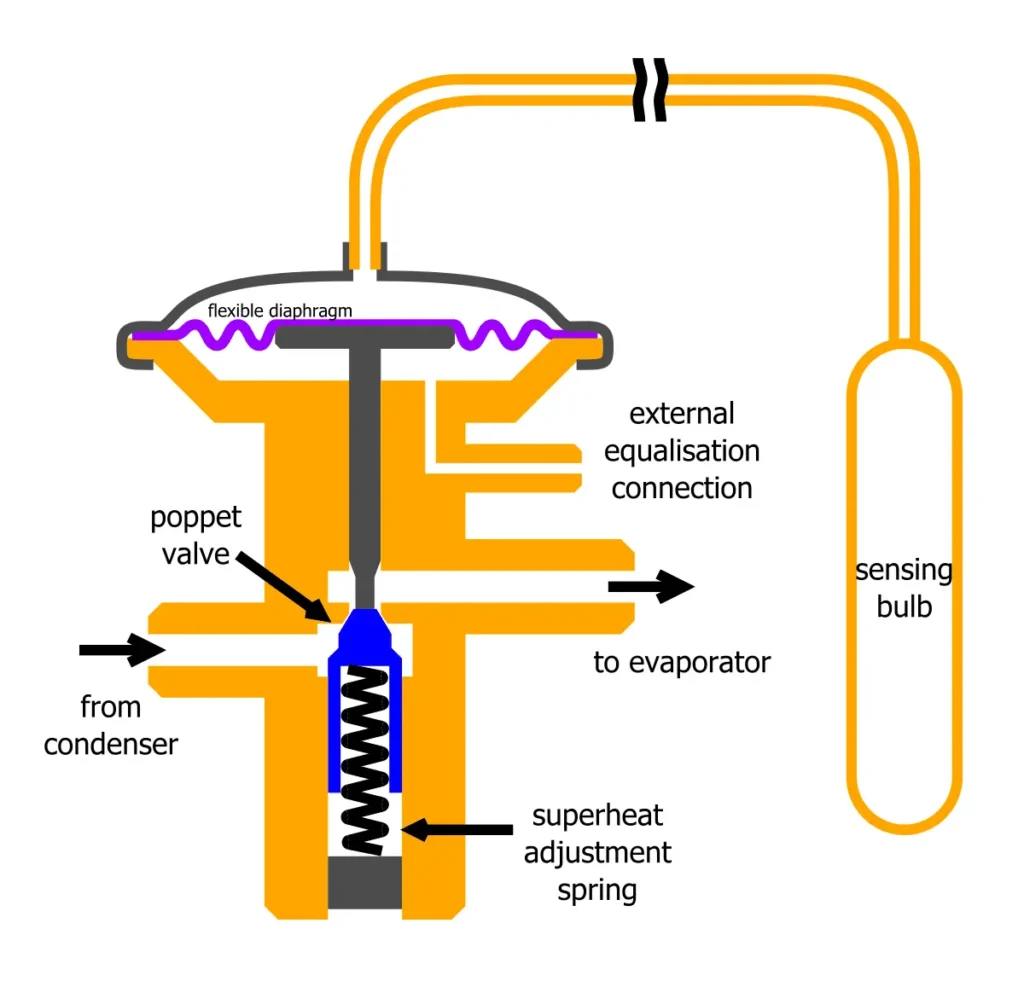

Thermostatic Expansion Valves (TXVs)

TXVs are traditional and reliable. They regulate refrigerant flow based on temperature. When the temperature goes out of the desired range, they adjust the flow to bring it back in line. They are often used in simpler systems, like residential air conditioning, where cost-effectiveness and reliability are important.

EEV vs TXV: Key Differences

Comparative Analysis of Functionality

EEVs are known for their high level of precision and responsiveness. They rely on electronic sensors to continuously monitor temperature, pressure, and superheat. This real-time data allows them to fine-tune the flow of refrigerant with incredible accuracy.

In contrast, TXVs operate on a simpler principle of temperature regulation, adjusting the refrigerant flow based on temperature variations. This fundamental difference sets the stage for their varying performance characteristics.

Operation, Control Mechanisms, and Responsiveness

EEVs, driven by electronic control systems, can adapt rapidly to changing conditions. Their sensors enable precise adjustments, which is especially valuable in situations where rapid and accurate control is required, such as in commercial air conditioning systems.

On the other hand, TXVs, with their temperature-sensing elements, are dependable and straightforward in operation. They offer reliability and have been a preferred choice in residential cooling systems where consistent performance and cost-effectiveness are essential.

Applications and Suitability

The choice between EEV and TXV depends on the specific HVAC application and its requirements, as well as considerations for system efficiency and precision.

Which Type of Valve is Better Suited for Specific HVAC Applications?

EEVs shine in applications with variable refrigerant flow and complex demands. Their ability to adjust refrigerant flow with precision makes them ideal for commercial air conditioning and variable load scenarios. TXVs, with their simplicity and reliability, are well-suited for residential cooling systems and other applications where cost-effectiveness and straightforward operation are paramount.

Considerations for System Efficiency and Precision

EEVs offer the advantage of precise control. They can respond swiftly to changing conditions, optimizing energy usage and temperature regulation. This precision often results in improved overall system efficiency, making EEVs a top choice for those who prioritize energy savings.

TXVs, while not as quick to respond, provide reliable performance and are often more budget-friendly. They are a solid choice for situations where consistent and cost-effective cooling is the primary concern.

EEV vs TXV: Advantages and Disadvantages

Electronic Expansion Valves (EEV)

Advantages

- Precision Control: EEVs offer highly accurate refrigerant flow control, resulting in superior temperature regulation.

- Energy Efficiency: Their responsiveness improves energy efficiency, reducing operational costs.

- Adaptability: Ideal for complex systems and variable load scenarios.

- Reduced Compressor Load: EEVs can alleviate stress on the compressor, potentially extending its lifespan.

- Enhanced Superheat Control: They excel in maintaining the desired superheat levels.

Disadvantages

- Complex Installation: EEVs may require more sophisticated control systems and expertise during installation.

- Higher Initial Cost: The precision and technology come at a higher price point.

- Maintenance Sensitivity: The electronic components may require more attention to ensure continued reliability.

Thermostatic Expansion Valves (TXV)

Advantages

- Reliability: TXVs are known for their durability and straightforward operation.

- Cost-Effective: They are budget-friendly and offer good value for simpler HVAC systems.

- Low Maintenance: TXVs are less sensitive to maintenance issues than EEVs.

- Proven Technology: Their reliability makes them a trusted choice in the industry.

- Consistency: TXVs provide consistent performance over time.

Disadvantages

- Limited Precision: They are not as precise as EEVs in controlling refrigerant flow.

- Slower Response: TXVs may not adapt as swiftly to changing conditions.

- Less Suitable for Complex Systems: Their simplicity may limit their use in complex applications.

C. Impact on Performance and Maintenance

EEVs

- Performance: EEVs enhance system efficiency and precision, resulting in better temperature control and potential energy savings.

- Maintenance: Regular maintenance is crucial to ensure the electronic components function correctly.

TXVs

- Performance: TXVs offer reliable performance but may not achieve the same level of precision or energy efficiency as EEVs.

- Maintenance: They are generally less maintenance-sensitive, making them a robust and dependable choice for long-term use.

Read Also: Is a Chiller Part of an HVAC System?

EEV vs TXV: Energy Efficiency and Cooling Performance

| Aspect | Electronic Expansion Valves (EEVs) | Thermostatic Expansion Valves (TXVs) |

|---|---|---|

| Energy Efficiency | – EEVs provide precise and responsive control over refrigerant flow. – This precision minimizes energy wastage, resulting in high energy efficiency. – They adapt swiftly to changing conditions, optimizing overall system performance. | – TXVs, while reliable, may not achieve the same level of precision as EEVs in controlling refrigerant flow. – They tend to be less energy-efficient due to slower response times and less precise control. – This can lead to increased energy consumption in some cases. |

| Temperature Control | – EEVs excel in maintaining precise temperature control by fine-tuning the refrigerant flow. – They ensure consistent temperature levels and help prevent temperature fluctuations. | – TXVs, although dependable, may struggle to maintain precise temperature control in all situations. – They can be less effective at preventing temperature swings, particularly in variable load scenarios. |

| Cooling Performance | – EEVs contribute to better cooling performance by maintaining ideal temperature levels consistently. – They offer improved humidity control, resulting in enhanced comfort. | – TXVs provide reliable cooling performance, but their precision is lower than that of EEVs. – Cooling performance may vary and be less consistent, especially in situations with fluctuating load conditions. |

| Overall Impact | – EEVs are a top choice for those who prioritize energy savings, precision temperature control, and consistent cooling performance. | – TXVs are a dependable choice for simple systems with cost-effectiveness and reliability in mind. – They may not provide the same level of efficiency or precise temperature control as EEVs. |

Choosing the Right Valve

Factors to Consider

- The Complexity of the System: If your HVAC system is intricate or has varying loads you may want to consider using EEVs due, to their precision.

- Budget: Keep your budget in mind as TXVs generally have a cost compared to EEVs.

- Reliability: For systems that require performance TXVs are often considered more reliable and cost-effective.

- Energy Efficiency: If saving energy is a priority for you using EEVs can provide control. Help achieve higher energy efficiency.

- Maintenance Expertise: Consider the availability of maintenance expertise as EEVs may require care.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are crucial for ensuring the operation of your HVAC system. Here are some tips;

Maintenance:

- Regular Checkups: Schedule maintenance checks to ensure both EEVs and TXVs are functioning optimally.

- Cleanliness: Keep all components free from debris to prevent clogs.

- Calibration: Make sure that EEVs are accurately calibrated for operation.

- Sensor Checks: For EEVs regularly inspect and maintain the sensors.

- Lubrication: Apply lubrication as needed for any moving parts, within the valves.

Common Issues and Solutions:

- Frost Formation:

If you notice frost forming on the valve it could mean that there is a problem, with the refrigerant or that the settings are incorrect. It’s advisable to seek help, in cases. - Address leaks promptly as they can impact the efficiency of your system. Leaks are an issue that needs attention.

- When a valve sticks or doesn’t modulate properly it can cause temperature fluctuations. In some situations, it might be necessary to clean or replace the valve.

- If electronic sensors fail it can lead to malfunctioning of the valve. Sensor replacement or calibration is required in cases.

- In case your TXV is not providing cooling it might need adjustment or replacement.