Delta T in HVAC: If you have ever wondered how to measure the performance and efficiency of your HVAC system. In that case, you may have encountered the term “delta T.” Delta T, or the difference between the supply and return air temperatures, is one of the most commonly used metrics in the HVAC industry. But what does it mean, and why does it matter? In this blog post, we will explain everything you need to know about delta T in HVAC, including calculation, Increasing tips, what it means for different types of systems, and what causes it to vary.

How to calculate delta T in HVAC

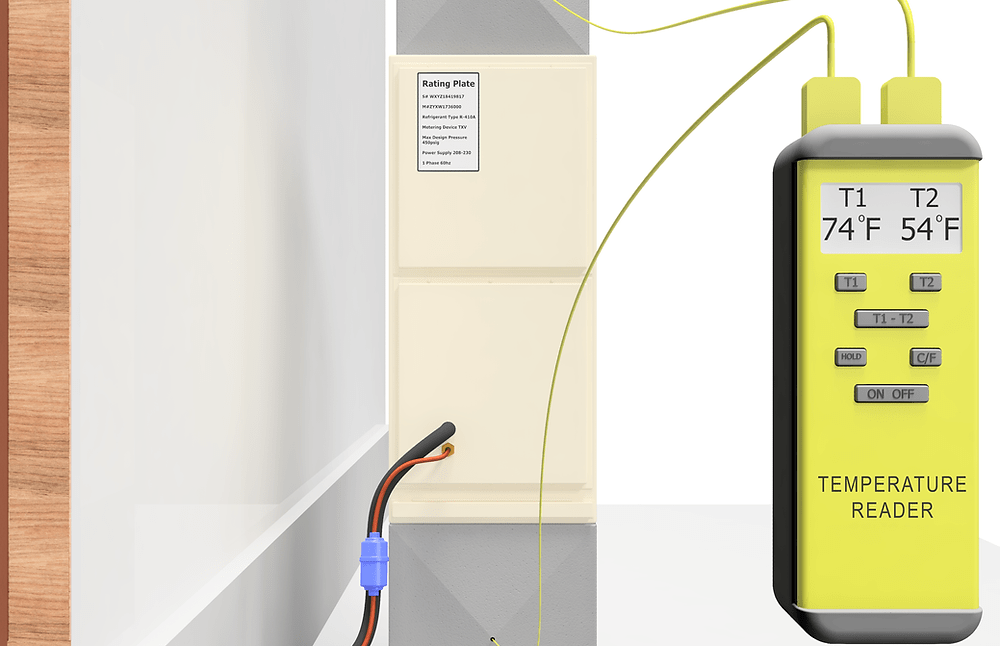

Calculating delta T in HVAC is simple: you need to subtract the return air temperature from the supply air temperature. For example, if the air entering the evaporator coil is 75°F and the air leaving the coil is 55°F, the delta T is 20°F. You can use a temperature meter with a probe to measure the air temperatures before and after the coil or use a thermostat with a duct sensor that can automatically calculate delta T for you.

The Equation of Delta T is: ΔT = T2 – T1

How to increase delta T in HVAC

Improving Delta T in HVAC for Efficiency: Enhancing

Delta T in HVAC improves heat transfer efficiency, lowers energy bills, and enhances comfort. Key factors influencing delta T include airflow, refrigerant charge, humidity, and system design. Here are tips to boost delta T:

- Regular Air Filter Maintenance: Replace or clean filters regularly to maintain proper airflow through the coil, preventing a decrease in delta T and reducing system workload.

- Optimize Blower Speed: Consult a professional to find the ideal blower speed, ensuring optimal heat exchange between air and coil.

- Monitor Refrigerant Charge: Measure refrigerant pressure using a gauge or manifold, comparing it to manufacturer specifications to maintain efficient heat transfer.

You can also learn more about 11 Common HVAC Mistakes That Can Cost You Money And Comfort.

- Humidity Control: Use a dehumidifier or variable speed system to control humidity, preventing a decrease in delta T caused by increased latent heat load.

- Selecting the Right System Design: Different HVAC systems have varying delta T ratings based on water or refrigerant temperature and flow rate. Choose a system aligning with your cooling needs and desired delta T. For instance, a chiller system may have a delta T of 10°F, while a heat pump system may have a delta T of 30°F.

What is delta T in the chiller?

Chiller Basics: Efficient Cooling with Water

A chiller, part of the HVAC system, uses water or water-glycol for cooling. Comprising a compressor, condenser, expansion valve, and evaporator involves compressing refrigerant and releasing heat in the condenser to the water or water-glycol mixture. This mixture circulates through a cooling tower or dry cooler, cooling before returning to the chiller. The expansion valve reduces refrigerant pressure, sending it to the evaporator to absorb heat from the water or water-glycol mixture. The cooled mixture circulates through the air handler or fan coil, cooling the air.

Delta T in Chiller: Performance Indicator

Delta T in a chiller measures the temperature difference between the water or water-glycol mixture at the evaporator’s inlet and outlet. For instance, if the mixture enters at 54°F and exits at 44°F, the delta T is 10°F. This metric crucially reflects chiller performance and efficiency. A higher delta T indicates efficient heat removal, reducing energy consumption and the flow rate of the water or water-glycol mixture. Conversely, a lower delta T suggests less effective heat removal, potentially increasing energy consumption and flow rate.

What causes delta T in HVAC

Delta T in HVAC results from heat exchange between air and the coil. The heat exchanger coil transfers heat between the refrigerant and air. Heat transfer hinges on temperature differences, coil surface area, heat transfer coefficient, and mass flow rate of air and refrigerant. Higher temperature differences yield more significant heat transfer and increased delta T, while lower differences lead to the opposite.

Factors Affecting Delta T in HVAC

Airflow

The air passing through the coil influences heat transfer. Increased airflow shortens contact time, heightening turbulence and improving delta T. Conversely, reduced airflow extends contact time, diminishing heat transfer and delta T.

Refrigerant Charge Impact on Heat Transfer

Refrigerant volume affects heat transfer by altering temperature and pressure. Higher charges lower temperature and pressure, reducing heat transfer and delta T. Lower charges raise temperature and pressure, increasing heat transfer and delta T.

You can also learn more about Why Does Your Heat Pump Keep Tripping Breaker- Reasons In 2023

Humidity’s Role in Heat Transfer

Air humidity impacts heat transfer by changing the latent heat load. Higher humidity decreases heat transfer and delta T, while lower humidity increases them.

Influence of System Design on Heat Transfer

HVAC system type and size impact heat transfer by modifying water or refrigerant temperature and flow rate. Different systems have distinct delta T ratings. For instance, a chiller system may have a 10°F delta T, while a heat pump system may have a 30°F delta T. Select a system aligned with your cooling needs and desired delta T.

What is a good Delta T for HVAC?

A suitable HVAC delta T aligns with cooling needs and maximizes system efficiency. As different HVAC systems and rooms have varying cooling loads, there’s no universal answer. However, you can use these ranges as a general guide:

- For a single or two-speed compressor system in cooling mode, aim for a delta T between 18°F and 22°F.For a variable-speed system in cooling mode, target a delta T between 14°F and 23°F.

- Chiller systems in cooling mode should maintain a delta T between 8°F and 12°F. Heat pump systems in cooling mode typically operate best with a delta T between 25°F and 35°F.

These ranges may vary based on system design, airflow, refrigerant charge, humidity, and outdoor conditions. Always consult manufacturer specifications and professional recommendations to determine the optimal delta T for your system.

How to Get the Correct Delta T in HVAC Systems

Getting the correct delta T in HVAC systems is crucial for ensuring your system’s best performance and efficiency. A correct delta T means that your system removes the right amount of heat from the air, which can lower your energy bills and increase your comfort. To get the correct delta T in HVAC systems, you need to follow these steps:

- Measure Delta T: Use a temperature meter or a thermostat to measure air temperatures before and after the coil, at least annually or more, if needed.

- Compare with Expected Range: Check measured delta T against your system’s expected range. Refer to suggested ranges or consult manufacturer specifications. If aligned, your plan is working; if not, troubleshoot.

Dont forget to Learn more about Are Furnaces Dangerous?

- Troubleshoot: Identify issues if delta T deviates. Use tips for airflow, refrigerant charge, humidity, and system design. Professional HVAC services can inspect and repair.

- Maintain Regularly: Sustain optimal delta T by cleaning/replacing the air filter monthly or as needed. Periodically check and adjust blower speed, refrigerant charge, and humidity. Schedule professional HVAC tune-ups annually or more for older systems.

How to check delta T in HVAC

Checking delta T in HVAC is a simple and effective way to monitor the performance and efficiency of your system. You can check your delta T in HVAC by following these steps:

- Start your system and run it for 15 minutes to achieve a steady state.

- Identify the supply and return air ducts. The supply duct delivers cooled or heated air, while the return duct collects air from your rooms.

- Use a temperature meter with a probe to measure air temperature at the supply and return ducts. Insert the probe through a small hole or vent, or use a duct sensor.

- Calculate delta T by subtracting return air temperature from supply air temperature (e.g., if supply air is 55°F and return air is 75°F, delta T is 20°F). Compare your delta T with the expected range for your system. Refer to manufacturer specs or professional recommendations. If within the range, your system is functioning correctly. If it is too high or too low, a problem may require fixing.

Conclusion

Delta T is a crucial metric that measures HVAC performance and efficiency. It is the difference between supply and return air temperatures and shows the amount of heat removed. Delta T varies based on system type, design, airflow, charge, humidity, and outdoor conditions. Regular measurement, comparison, troubleshooting, and maintenance ensure the correct Delta T, leading to lower bills, increased comfort, and longer lifespan.